“We make metal things, but our product is people and community,” said Ron Hardman, the brand-new supplier of Air Force sabers to the United States Air Force Academy.

Ron is down-to-earth, and very personable. He got his start in metalworking and other trades by working with his father, George Hardman, a high school shop teacher in Wisconsin. “My dad started out as a Special Ed teacher, then switched to Shop. He noticed that he ended up having many of the same students coming through,” said Ron.

“My dad said I was ADHD (attention deficit hyperactivity disorder), but he didn’t classify me as that. He classified me as a shop class kid!” After school he would go to his father’s classroom and help him build all kinds of things.

This time with his father led him to become an apprentice at Woodward Governor Company at age 14. By the time he was 16 years old, he oversaw the CNC mill lathe. “This set me on a path, and was very transformational,” Ron explained.

As he grew up, Ron realized a need for the type of training his father gave him and started Kilroy’s Workshop in 2014. Now Ron is married with his own family, three daughters and a son. Two are married with their own families, but all of them (even Mom!) have helped with or participated in this unique metalworking school in Colorado Springs.

He started out with homeschoolers, as he assumed many of them would not have access to this kind of education. As the school grew, many public-school children joined after shop class was removed from schools, and even adults signed up. Ron stated that 70% of the 4,000 students that come through every year are public-schooled.

Ron and his family are extremely interested in community. They have a connection with the Wounded Warrior Project, Operation TBI (Traumatic Brain Injury) Freedom, and the RD (River Deep) Foundation. All these organizations work with wounded veterans. Ron invites these veterans to come and make projects and attend events at the school.

Whether it’s young people, parents, or veterans, the teachers and students are like family. When they see each other outside of class, they know each other. The school is a place where you get to “know people, a place to belong.”

Not only do the participants learn metalworking and blacksmithing, but they also can show off their stuff. I had not ever heard of the reality show “Forged in Fire,” but after interviewing Ron, I’d like to start watching it! Ron, some of his children, and many of his students have been participants on the program. In 2019, the show wanted to do a “Family Episode” and invited Ron back. Ron asked his then 20-year-old daughter, Jessica, to go to the show with him. She works full-time at Kilroy’s.

Watch Forged in Fire Season 7 Episode 12 | HISTORY Channel

They were up against a father-son team. In the first round, the fathers were competing against their children! They had to build a blade with items provided by the hosts. While the family members were each trying to win, there was a respect that they had for each other, and the important thing was for someone from the family to win.

Both fathers ended up winning this round, and in the next one, it was dad against dad. They were shown a weapon from history, and then had to go home, with 4 days to complete a replica. The producers had asked Ron what type of weapon they should choose for them to make, and he answered, “the hardest thing you can find.”

I absolutely love what comes next…the weapon? Inigo Montoya’s rapier from “The Princess Bride.” You haven’t watched it? You have to find it online and watch it! Best date movie ever! It was my husband Rich and my first date…we saw it in the theater!

Ron said that while on the show, he was dropping lines from the movie and had the judges laughing. When he presented the replica he had made, the judges asked to see it, and he replied, “As you wish.” He sat with his daughter and brought the book The Princess Bride. “I want to tell you about my sword,” he told her, opening the book.

“I’ll try to stay awake,” she replied. You’ll have to watch the movie to understand.

As we visit, I realize that we have a lot of connections…families working together, homeschooling, and family cult movies. But there’s another one…the Air Force Academy. A while back, we had heard rumors that there was a new supplier for the Air Force Academy saber. For the longest time, USAFA got them from Germany. At Parents’ Weekend 2024, we got to meet Ron. Before the Web Guy social, we were telling parents, “The new saber guy is going to be there.” And we heard that he wanted to talk to us, “the saber case people.”

Why does all this matter to you, a grad, cadet, or parent? It’s fun to know the people you purchase items from, that we’re real people (sometimes crazy people! Not you, Ron, I was referring to us). But also, we want to let you know about the high quality of the new sabers.

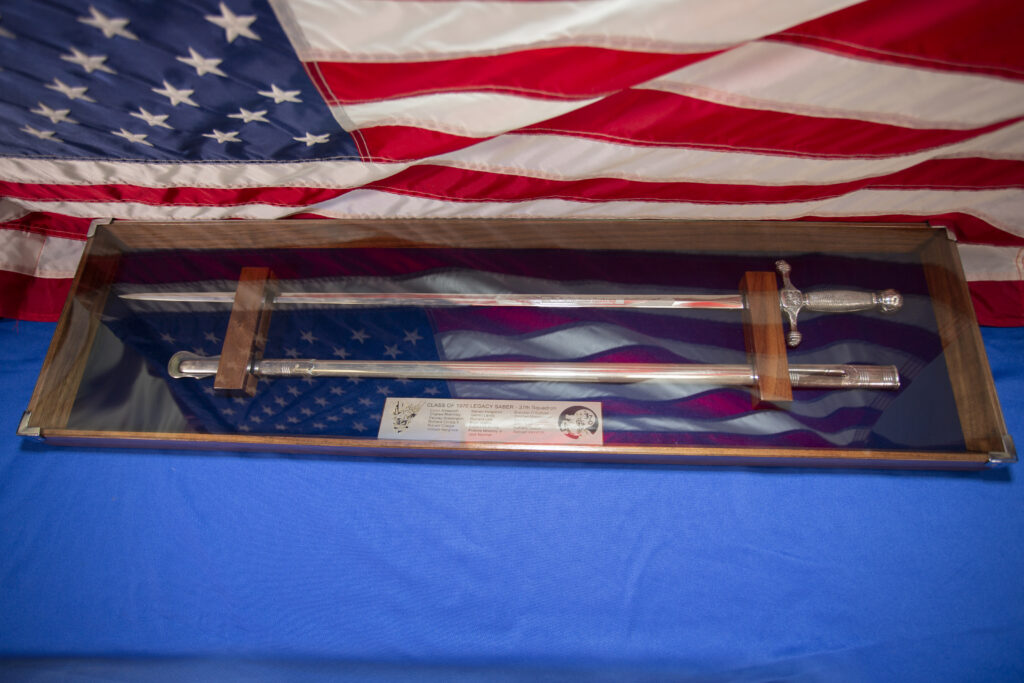

After watching Ron on “Forged in Fire,” (I did sneak a peek while writing this), I know that he knows his stuff. He won, by the way. He wants you to know that these new sabers are top of the line. He is using Aeb-L stainless steel. It is a vast improvement over the old sabers. In fact, he has been doing maintenance on the old ones for years, which is how he got the contract. A few months ago, USAFA brought him four hundred sabers from Germany that had not been etched with the Air Force Academy name and he saved the day.

If you’re wanting to go online and find out more about Ron and his company, you might be confused about seeing a school, Kilroy’s Workshop. Ron came up with a breakout company, Excalibur Outdoors, where they sell their creations.

When you do look at his school, know that these people are good at what they do. Sometimes there is the stigma of something not being so good because it is made by “students.” These students have been trained by a true professional, and they are good.

Back to the USAFA sabers…the old handles rattled, the new ones do not; they are solid. The handle is wire-wrapped, spinning done in-house around a core. They are not just stamped, like the old ones.

The new sabers are heat treated in-house. They are not just decorative, they are “zombie killers,” Ron said.

Older versions of the USAFA sabers could be found from various vendors, even knock-offs from China. These new high-quality sabers are ONLY available from the United States Air Force Academy Association of Graduates (USAFA AOG).

How to purchase one? Go to the AOG website and get on the waiting list: www.shop.usafa.org.

As if metalworking and teaching aren’t enough, Ron is a computer programmer and writer. He and his daughter Jessica co-authored a children’s book, Shadow Fox Sons of Liberty. Jessica is also the editor of their online magazine, Master Crafts Magazine, Home | Mastercrafts Mag. In addition, he created a non-profit, the Association of Independent Trade Schools (www.AITSonline.org). This organization fosters “the growth of trade schools,” and offers “resources, scholarships, and helps new trade schools.” Today there are approximately 40,000 trade schools in existence. Ron developed management software to help trade schools. Check it out at www.catalanpro.com.

To conclude, I asked Ron what motivates him to do all the incredible stuff that he and his family do, and he answered, “The people. They all have a story. The relationships. That’s the reason our staff started as students.” To find out more or to contact Ron, go to www.excaliburoutdoorsusa.com or www.kilroysworkshop.com.

We are honored and excited to be working with Ron and Excalibur Outdoors to bring you a beautiful heirloom to celebrate you or your loved ones’ hard work of graduating from the Air Force Academy.

If you need more motivation to purchase a saber, go to The Legacy Saber Project and read Steve Hoagland’s speech, and the “Because Every Grad Should Have One” testimonial Testimonials/Photo Library.